Launch deadlines are looming, your team is overloaded, and a tricky mechanical, electrical , thermal, or embedded component is stalling progress. Resolve it on schedule without burning out your engineers and adding cost

With your team maxed out on all projects they can’t tackle a critical component. I take it off your plate.

The launch is getting close and a single tricky component can hold up your roadmap and put pressure on your already-full team. Pulling engineers off their main projects or dealing with an unecessarily steep learning curve or hand holding puts the product line launch at risk.I’m a Product Launch Specialist. I take full ownership of these tough components, solving the high-stakes engineering problems your team doesn’t have time or expertise for. I deliver production-ready designs without guesswork.I work smoothly with your existing process so your engineers stay focused while I get the component done.If you want to unblock your roadmap and hit your product launch without burning out your team, book a 15-minute call using the link below.

For Mission-Critical Product Launches

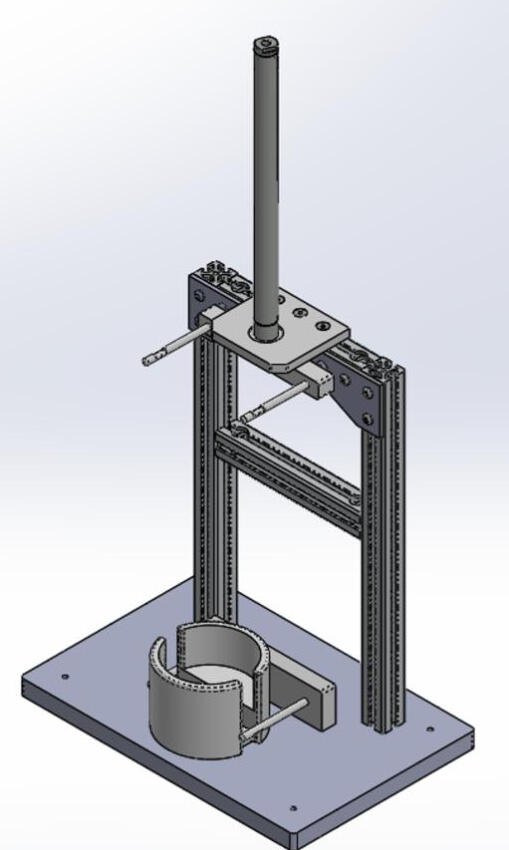

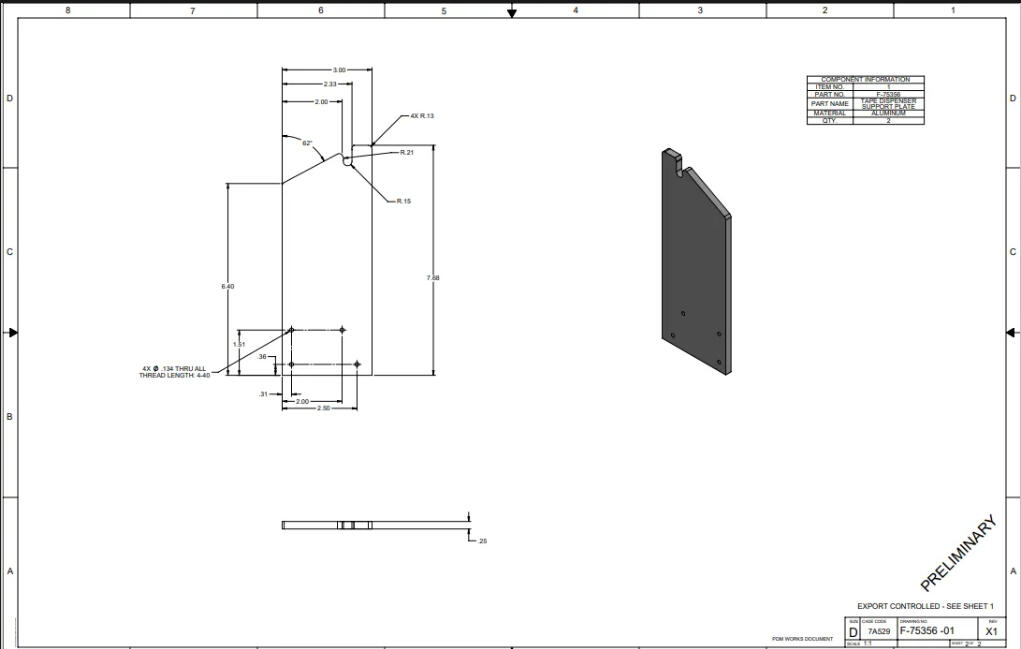

Mario has designed and engineered components for demanding environments from naval defense systems at Sparton Electronics to large-scale building products at Kingspan. His work includes mechanical parts, tools, and production fixtures that support mission-critical performance and reliable manufacturing.He brings hands-on experience with design for manufacturability and a strong understanding of how OEMs build products at scale. He’s designed tools that remove repetitive work for operators, created CAD templates that speed up engineering time, and built test fixtures to make sure designs meet tough requirements.Mario’s work has supported high-level teams, including the U.S. Navy and global manufacturers like Kingspan, helping them build products that perform well in the field and deliver clear value.

Book a Product Launch Derisking Session

What we can cover on a free 15 minute product launch session:• Pinpoint your launch blocker. Quickly identify whether the hold-up is new product introduction, packaging, material, motion, testing, or cost, and the fastest next step.• Find the critical engineering bottleneck. Highlight the one issue that’s stopping progress so your team can stay focused.• Catch manufacturability risks early. Avoid trial-and-error, rework, and costly surprises in production.• Spot hidden failure points. Tolerance stacking, fatigue risk, misaligned interfaces, tooling assumptions. We flag them before they hit your line.• Pressure-test costs and materials. See where costs come from and how to hit target price points for small or mid-volume runs.• Align your teams fast. Identify gaps between design, manufacturing, and leadership to prevent last-minute firefighting.• Leave with a clear action plan. Walk away with 1–3 concrete steps that get your component moving and protect your launch timeline

© Ronci Product Validation. All rights reserved.